blown film machine pdf

Designed specifically for Form-Fill-Seal Applications OPTIMEX II FFS. Machine Construction A cut-away drawing of a simple single screw machine is shown in Figure 1.

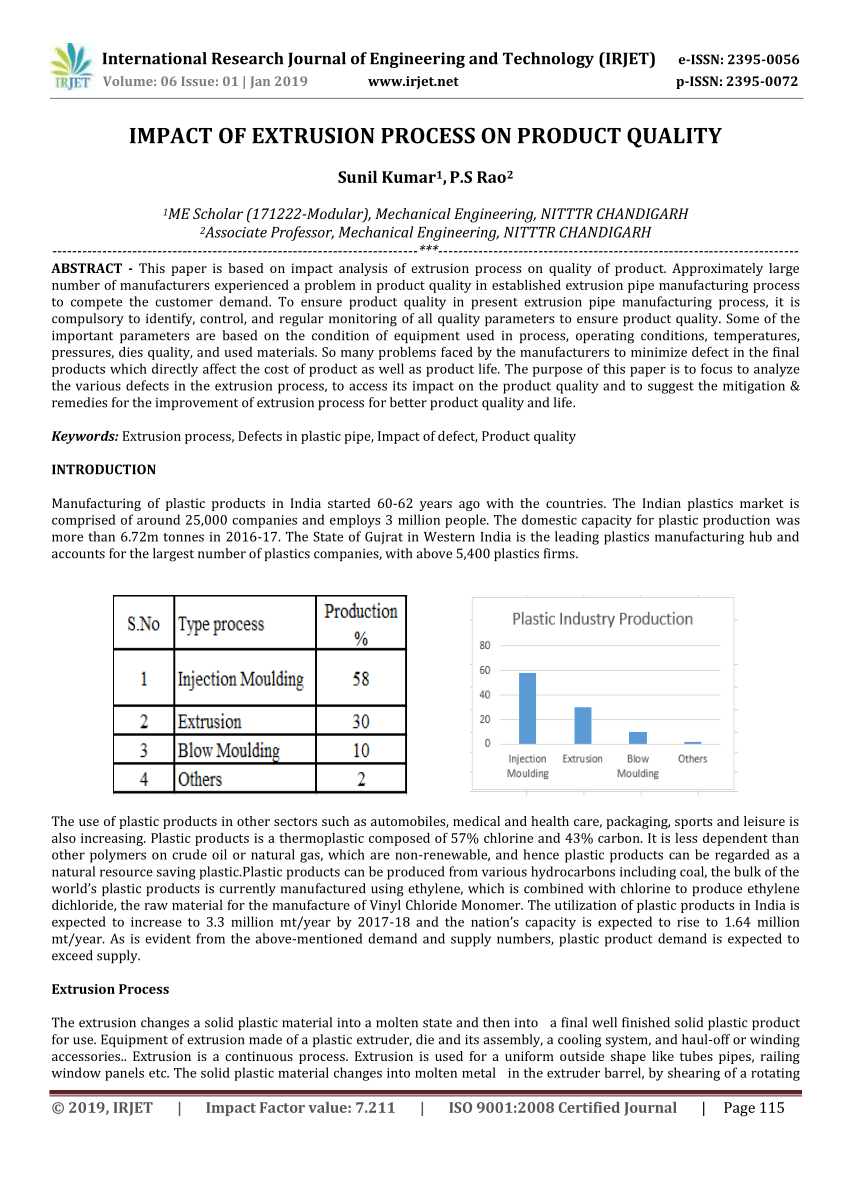

Pdf Impact Of Extrusion Process On Product Quality

1Auto Loader 2Air Compressor 3Rotary Die Head 4Double Side Winder Back to back winder 5Up and Down 6Embossing Cylinder 7Air Shaft.

. Film width available from 2000 4000mm excellent for heavy-duty bagsUnique die head and air ring design to achieve stable bubble and better even thickness film and bagGear box uses high torque and enforced lubrication systemAutomatic surface winder with uploading deviceOscillating haul-off. The tubular blown film process is efficient and economical and can produce a magnifi- cent array of products from a light gauge clear converter film to heavy gauge construction film which when slit and opened may measure 40 feet or more in width. All our blown film extrusion machines are equipped with Rossi gearbox which is made in Italy ABB inverter as standard devices and we use PID thermos controller SCR for our heating system.

The sheets and films are formed by this process. Two-Color Co-Extrusion Blown Film Machine. Multilayer Blown Film Machine.

Whose width can vary trcn-. D-73773 Aichwald phone 49 1577 5329827. Polypropylene blown film machine Polypropylene blown film machine is suitable to blow polypropylene PP plastic film widely uses in goods for civilians and the industrial product and Contact Supplier Multi layers coextrusion film blowing machine 5 layers.

Film width of blow film machine available from 150mm to 1200mm 5 to 48 inch and can be customized depending on customers requirement suitable for both HDPELDPE film and recycle film. SmartFlex Blown Film lines 1 3 and 5 layers characterized by a competitive investment level maximized flexibility for different applicationsrecipes power consumption reduction functional and compact layout featuring frames modularity. Several billion pounds of polymer mostly polyethylene are processed annually by this technique 1.

Standards that Deliver Value OPTIMEX II OPTIMEX II is the optimized extrusion line to serve a defined range of products in the 3- and 5-layer Polyolefine Dedicated POD film section. This shows the arrangement of the different parts of the machine. Classicx multi-layer 3-5 non barrier blown film machine introduction for classic models currenttv-aeilable blcmn machines are appltabe to enth 3-layer and 5-layer tilrrs.

The total area is 32000 square meters the modern standard workshop covers 20000 square meters. This up to 11-layer blown film line is individually designed for your challenging products. We have 160 employees and 70 of them are senior technicians.

Blown Film Troubleshooting Guide Bubble Instability Chatter Die Lines Poor Heat Seal Melt Fracture Gauge V ariation cont Gels Causess Possible Solutions Dirty Air Ring Cont Check the seal between the air ring and die Check hoses for kinks or bends restricting air flow Surging of the extruder Check drive speed of the extruder. Blown film is a major processing technique for producing a biaxial melt drawn film. Bandera Blown Film extrusion range includes.

Processing our understanding of the extrusion of tubular blown film remains in the stage of art. Blown film extrusion is one of the most commonly used thin gauge fabrication processes for manufacturing plastic films in the world. To cmtrol tech-mbwto the.

Auch Folien Technik e. Film width 300 1500mm. All the screw materials are imorted from Japan and.

ABA - HDPE and LDPE. Basic Blown Film Line Figure 1 Elements of Blown Film Figure 2 3 Main Arena of Action. PDF On Dec 19 2012 John Vlachopoulos and others published Blown Film Dies Find read and cite all the research you need on ResearchGate.

Working of Blown Film Extrusion Machine Units Components Purpose Pallet feeding unit Material conditioner. This technique uses air pressure to produce a transverse direction draw and a higher speed haul-off roll speed to provide a machine direction draw. Techno FLEX Blown Film lines for the production of multi-layer film 3.

The blown film extrusion process can produce magnificent arrays of products however. Extruder screw 70 mm ld 24 die diameter 250 mm and 300 mm gap 09 mm and 12 mm corona treatment wrapper 1600 mm working width. Given therefore a single screw machine is being described that has a screw of diameter 60 mm and a length of 24 screw diameters that is a LD ratio of 241.

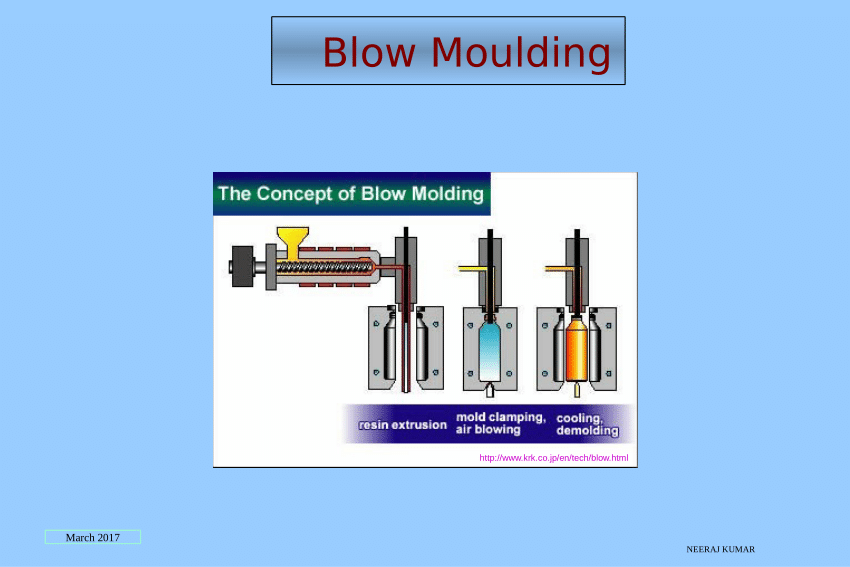

The bottleneck in blown film extrusion lies in the cooling of the fast moving thin melt film It is important to understand that three elements of the blown film process are of first order importance to be able to produce near uniform gauge blown. Blown film extrusion is a continuous process and films of many sizes can be made by it by varying the rpm of conveyors and motors. This type of extrusion utilizes two or more extruders to melt and deliver a steady volumetric throughput of different viscous plastics to a single extrusion head die which extrude the materials in the desired form.

Technical system exercise to ensure nigner mm. Blown film extrusion is used for production of sheets and films of different polymers like HDPE LDPE PS and PE. The polymer is melted in an extruder and the hot melt is pumped through a die to form a thin-walled tube which is simultaneously axially drawn and radially expanded.

Coextrusion of blown film Coextrusion is the extrusion of multiple layers of material simultaneously. Blown film extrusion is the most important process for the production of plastic films ranging in thickness from 05 mm to as thin as 5 μm according to Butler 1. Mono-blown film lin in good working condition for processing LD and LLD-PE film width max.

Dalian Jianda Plastics Machinery CoLtd founded in 2000is specialized in RD and production of single double three and five layers of plastic film blowing machine. 4555mm or 55mm65mm screw. T-shirt bags garbage bags flat bag and others.

All Rajoo Engineers Ltd Catalogs And Technical Brochures

Extrusion Machine Operator Resume Samples Qwikresume

Film Blowing An Overview Sciencedirect Topics

Extrusion Machine Operator Resume Samples Qwikresume

Extrusion Machine Operator Resume Samples Qwikresume

Pdf Simulation And Design Of Extrusion Dies Semantic Scholar

1 Schematic Of The Film Blowing Process Download Scientific Diagram

Extrusion Process Definition Working Principle Types Applications Advantages And Disadvantages Notes With Pdf Learn Mechanical

All Windsor Machines Limited Catalogs And Technical Brochures

Extrusion Machinery Jwell Extrusion Machinery Co Ltd Shanghai Pdf Catalogs Technical Documentation Brochure

Pdf Design And Fabrication Of Extrusion Machine For Recycling Plastics

All Windsor Machines Limited Catalogs And Technical Brochures